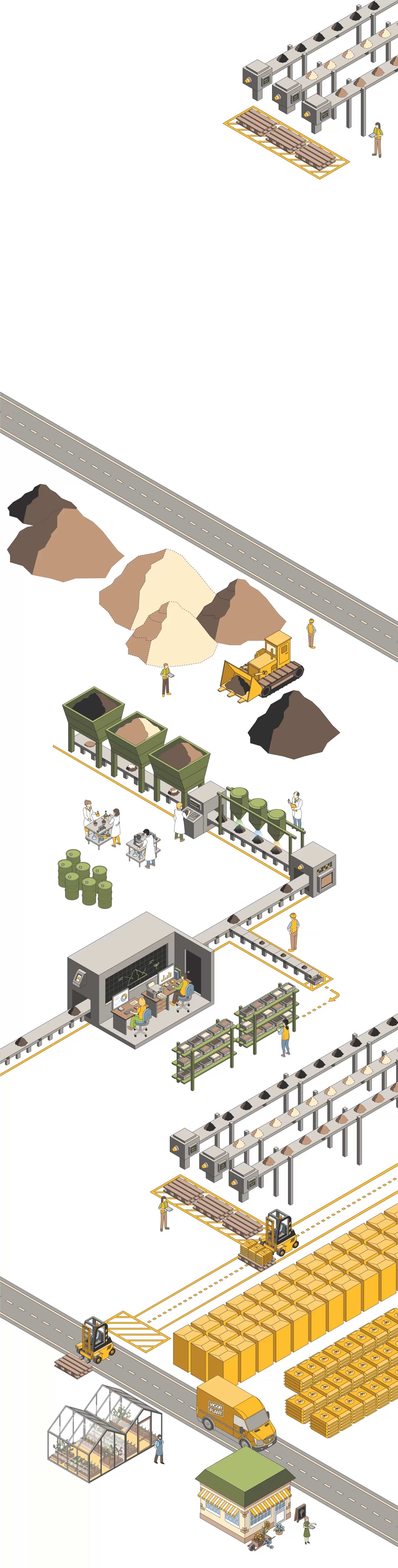

Not all soils are the same

In a bag of Vigorplant soil, there is so much more than just "soil". Researching for raw materials, creating our own blends to obtain exactly the desired result, carrying out qualitative analyses along the entire production process: these are the factors that allow us to offer you a constant high-quality standard in every Vigorplant product.

Blonde peat

Coconut fibre

Baltic peats

Clay

Conifer fibre

Volcanic lapilli

Bark

Irish peat